Today, the industry of additive technologies is quite diverse: dozens of printing methods have been developed, hundreds of specialized printers have been created, and how many more will be produced. One of the first methods of 3D printing is mask stereolithography, or SGC.

Today, the industry of additive technologies is quite diverse: dozens of printing methods have been developed, hundreds of specialized printers have been created, and how many more will be produced. One of the first methods of 3D printing is mask stereolithography, or SGC.

The method was created 31 years ago by Israeli developers from Cubital Ltd. After completion of the organization’s activities, Objet Geometries Ltd and Stratasys moved to the right of invention. The company that competed with the two gave another version of the name to this method, namely, Film Transfer Imaging, or FTI.

SGC Technology

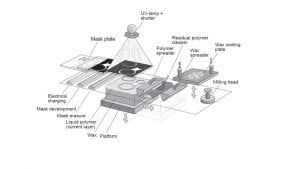

The principle of the method is the stepwise application of thin layers of resin from photopolymers. After that, they are exposed to ultraviolet irradiation from the photomasket or the “mask” of the necessary contour. Inside the cavity is poured with a special wax. As a result, polymerization of the main material takes place, that is, its transformation into a solid state.

If necessary, all the excess material is removed and the work surface is cleaned to print the next product. After creating the final model, the wax is melted, and the finished product remains.

Advantages and disadvantages of SGC

There are several advantages and disadvantages of this method.

Pros:

- do not need to create supporting structures;

- high precision of printing due to machining of each layer;

- high level of productivity;

- cheapness of printed items;

- a huge range of post-processing options.

Minuses:

- a lot of waste that increases the cost of the facility;

- noisy printing process;

- expensive printer design setup;

- under the influence of water, objects will crumble due to the specific nature of the material;

- the complexity of creating a model because of the huge number of masks.

SGC technology applications

At the moment, this method is rarely used. There are several of its new variations, but they are no different from LED printing, for which digital projectors are already used. Moreover, many new technologies have been created that do not have the disadvantages mentioned above, but on the contrary have a lot of advantages.

Consumables

For printing on this technology, only the resins of the photopolymer are used. To select the type of material required, it is important to take into account the technological features of production. For example, for machining a polymer with certain characteristics is needed. The most commonly used are photopolymers, which have the same strength and toughness as ABS plastic.

Image Credit: wikipedia/ “https://en.wikipedia.org/wiki/Solid_ground_curing#/media/File:Schematic_Diagram_of_Solid_Ground_Curing_Process.jpg” Zay Yar Myint